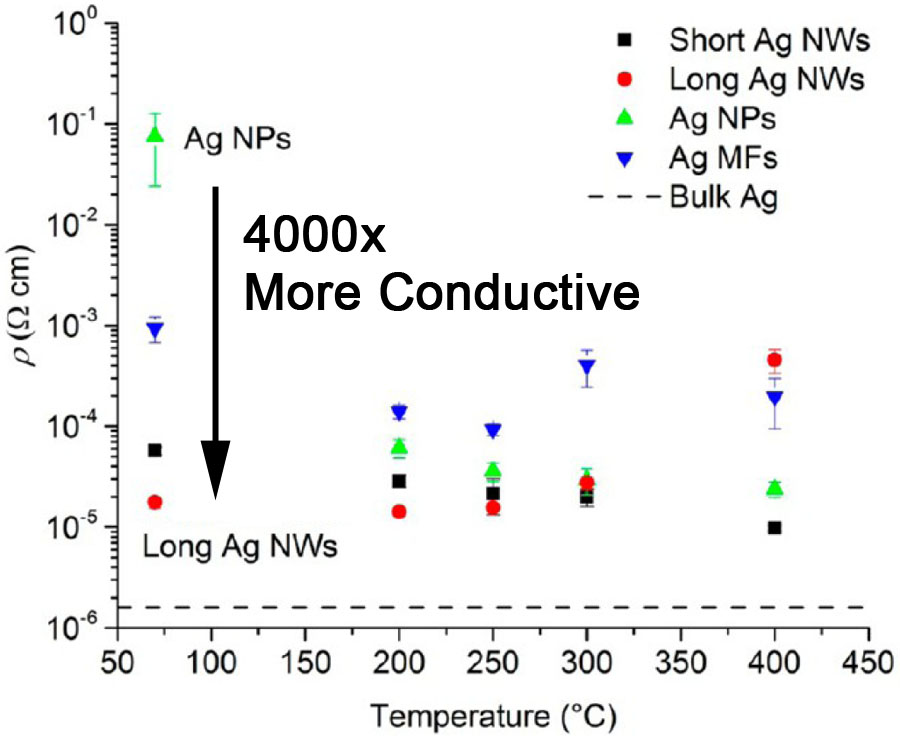

We sought to clarify how the high aspect ratio of nanowires can be leveraged to develop new nanowire-based materials and devices. For example, by studying the effect of nanostructure morphology on the electrical resistivity of silver nanostructure films, we found that films of silver nanowires were 4000 times more conductive than films of nanoparticles (see Figure 1) after coating and drying at 70°C (ACS Appl. Mater. Interfaces, 2017). This is due to the fact that the high aspect ratio of nanowires reduces the number of resistive contacts through which electrical current must travel compared to a nanoparticle film. This property was subsequently used in a collaboration with Aaron Franklin (Electrical and Computer Engineering, Duke) to eliminate high temperature (>200°C) sintering steps and enable in-place printing of carbon nanotube transistors (ACS Appl. Nano Mater. 2018). We also collaborated with the Franklin lab to study the effects of nanostructure morphology on the properties of printed contacts in thin-film transistors made from carbon nanotubes (Adv. Funct. Mater., 2018). Silver nanoflakes produced the lowest contact resistance interfaces, nanoparticles produced the smallest feature sizes, while nanowires enabled the lowest processing temperature. These studies illustrate that the high aspect ratio of metal nanowires allows them to serve as highly conductive inks that, unlike conventional nanoparticle inks, do not require sintering at high temperatures to become conductive. The ability to print conductive traces at low processing temperatures opens up the possibility to print electronics directly onto biological substrates.

Figure 1. Resistivity vs. sintering temperature for different nanostructure morphologies. See the paper for more details

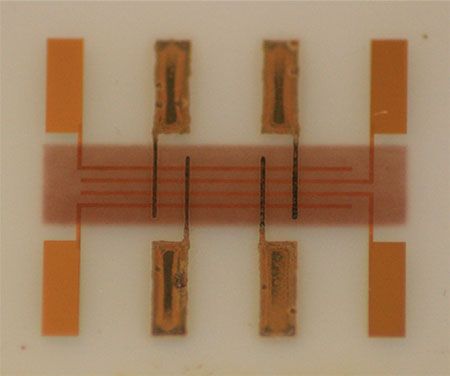

High-performance memristor-based memory devices typically employ a solid-electrolyte 2-50 nm thick, but such thin, uniform layers cannot be printed from solution. Printed memristors usually use thicker films and, as a result, their data retention time or number of switching cycles were far below that of Flash memory. We hypothesized we could address this challenge of obtaining the properties of a thin film in a thick film by using core-shell nanowires. We coated copper nanowires with 20-nm-thick SiO2 shells that could serve as a resistive switching layer. We demonstrated a non-volatile memory based on Cu–SiO2 core–shell nanowires that could be printed from solution and exhibited on-off ratios of 106, switching speeds of 50 ns, a low operating voltage of 2 V, and at least 104 cycles of operation without failure. Each of these metrics is similar to or better than Flash memory (the write speed is 20 times faster than Flash), the combination of which had not been previously achieved for a solution-processed memory device (Nanoscale Horiz., 2016). We subsequently created a three-dimensional, fully-printed, 16-cell crossbar array (Figure 2) of these nanowire- based memristors (J. Electron. Mater., 2017). The excellent performance of these fully printed memristors could help enable the creation of fully printed RFID tags and sensors with integrated data storage. This work demonstrates that nanowires coated with thin shells of memristive materials can enable a film that is several microns thick to behave like a memristive switch only 20-nm-thick.

Figure 2. Fully-printed, 16-cell crossbar array of nanowire-based memristors. See the paper for more details

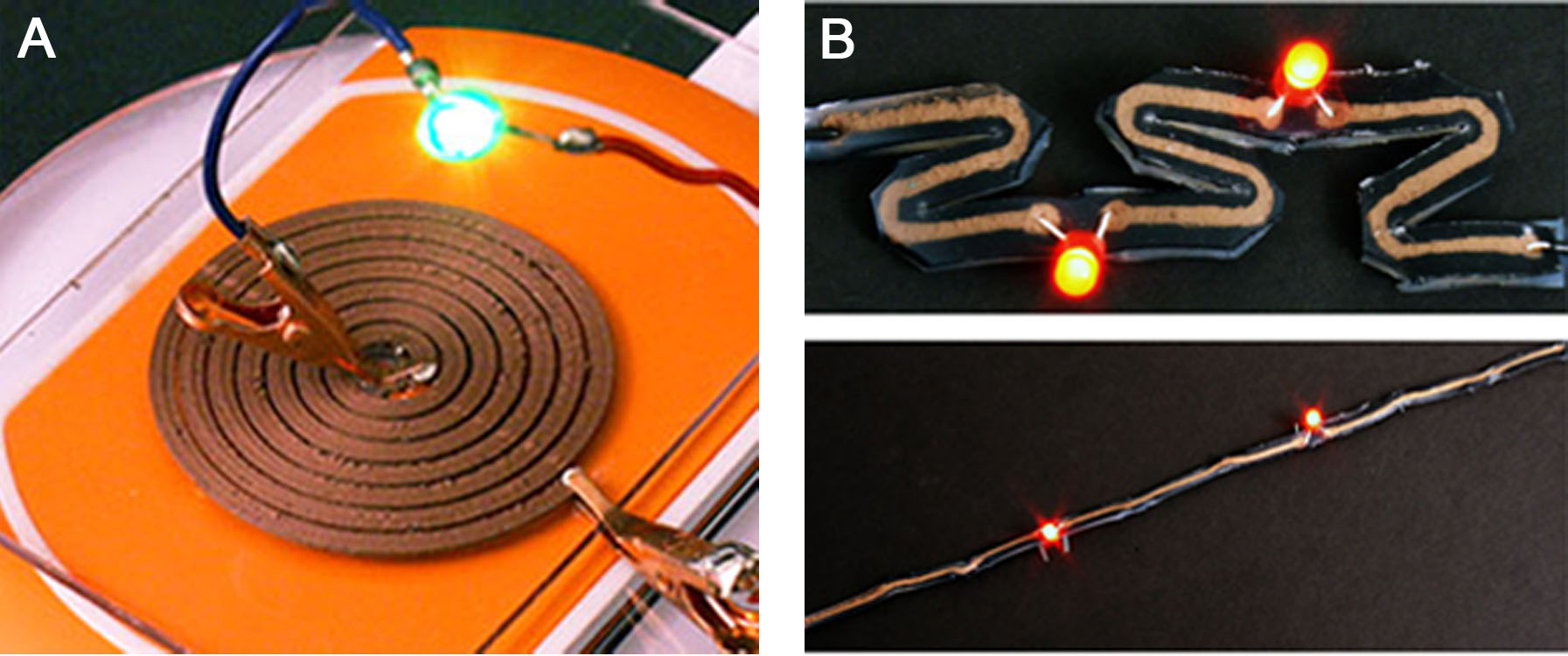

One challenge in using nanomaterials is the small scales at which they are often produced. To enable their use in conductive composites, we developed a multigram synthesis of Cu-Ag core-shell nanowires (Part. Part. Syst. Char., 2018). By using a relatively large copper nanowire diameter (240 nm), we found a Ag:Cu mol ratio of 0.04 was sufficient to coat the nanowires with ~3 nm of Ag. This thin silver coating minimizes the use of costly silver while greatly lowering the inter-wire contact resistance and protecting the copper nanowires from oxidation. We used these nanowires to create a 3D printing filament with a resistivity of 0.002 W cm, which is >100 times more conductive than commercially available carbon-based 3D printing filaments (see Figure 3A). The conductivity of composites containing 5 vol% of 50-μm-long Cu-Ag nanowires is greater than composites containing 22 vol% of 20-μm-long Ag nanowires or 10-μm-long flakes, demonstrating that high-aspect ratio Cu-Ag nanowires enable the production of highly conductive composites at low volume fractions. Cu-Ag nanowires were also used to create a stretchable composite (see Figure 3B) with a conductivity under strain that is superior to any composite with a conductivity greater than 1000 S cm-1 (ACS Nano, 2018). Composites with 10 vol% nanowires could retain a higher conductivity after 50 cycles of stretching than composites containing 25 vol% of silver microflakes. These studies demonstrate that silver-coated copper nanowires can achieve higher conductivities and stretchability in conductive composites than standard conductive fillers such as silver microflakes.

Figure 3. (A) Wireless power transfer coil printed with Cu-Ag NW-based filament. (B) Stretchable, conductive Cu-Ag nanowire composite. See paper-A and paper-B for more details

Related Publications:

Ye, S.; Stewart, I.E.; Chen, Z.; Li, B.; Rathmell, A.R.; Wiley, B.J. How Copper Nanowires Grow and How To Control Their Properties. Acc. Chem. Res. 2016, 49, 442 451.

Stewart, I.E.; Kim, M.J.; Wiley, B.J.; Effect of Morphology on the Electrical Resistivity of Silver Nanostructure Films. ACS Appl. Mater. Interfaces, 2017, 9, 1870.

Catenacci, M.J.; Flowers, P.F.; Cao, C.; Andrews, J.B.; Franklin, A.D.; Wiley, B.J.; Fully Printed Memristors from Cu–SiO2 Core–Shell Nanowire Composites. J. Electron. Mater., 2017, 46, 4596-4603.

Cruz, M.A.; Ye, S.; Kim, M.J.; Reyes, C.; Yang, F.; Flowers, P.F.; Wiley, B.J. Multigram Synthesis of Cu‐Ag Core–Shell Nanowires Enables the Production of a Highly Conductive Polymer Filament for 3D Printing Electronics. Part. Part. Syst. Char. 2018, 1700385.

Catenacci, M.J.; Reyes, C.; Cruz, M.A.; Wiley, B.J. Stretchable Conductive Composites from Cu–Ag Nanowire Felt. ACS Nano 2018, 3689.

Cardenas, J.A.; Catenacci, M.J.; Andrews, J.B.; Williams, N.X.; Wiley, B.J.; Franklin, A.D. In-Place Printing of Carbon Nanotube Transistors at Low Temperature. ACS Appl. Nano Mater. 2018, 1863.

Manning H.G.; Niosi, F.; Gomes da Rocha, C.; Bellow A.T.; O’Callaghan, C.; Biswas, S.; Flowers, P.F.; Wiley, B.J.; Holmes, J.D.; Ferreira, M.S.; Boland, J.J. Emergence of winner-takes-all connectivity paths in random nanowire networks. Nat. Commun. 2018, 3929.

Cardenas, J.A.; Upshaw, S.; Williams, N.X.; Catenacci, M.J.; Wiley, B.J.; Franklin, A.D. Impact of Morphology on Printed Contact Performance in Carbon Nanotube Thin-Film Transistors. Adv. Funct. Mater. 2018, 1805727.